Industrial Coffee Mill Overview: Boost Effectiveness and Quality

In the affordable landscape of coffee production, choosing the right industrial coffee grinder plays an essential role in enhancing both efficiency and item quality. Recognizing the nuances of various mill types and key attributes-- such as adjustable grind setups and durable building-- can substantially affect the last flavor account of the coffee.

Recognizing Grinder Types

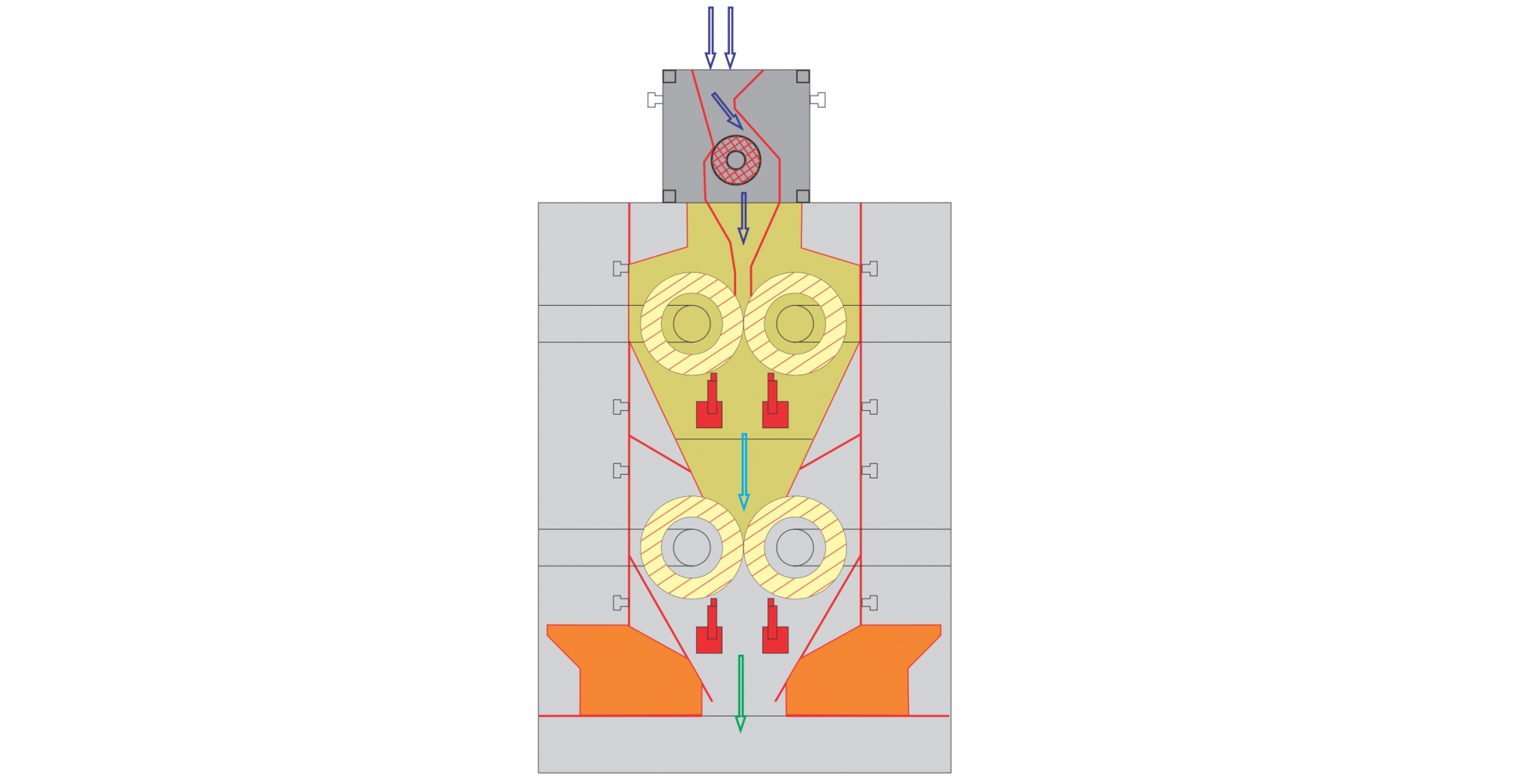

When selecting an industrial coffee grinder, comprehending the various kinds available is critical for maximizing both flavor removal and operational performance. The 2 key types of grinders are blade mills and burr mills.

Inevitably, choosing the appropriate kind of mill is important to maintaining high quality and performance in coffee production, making it crucial for companies to purchase premium burr mills for optimal results.

Secret Features to Think About

Picking a commercial coffee grinder requires cautious consideration of a number of key attributes that can significantly affect both performance and the overall coffee experience. Among the main elements to assess is the grinding system. Burr grinders are generally chosen over blade grinders, as they offer a constant work dimension, which is important for optimal removal and flavor.

One more important feature is the grinder's ability. A functional mill with several settings allows you to customize the work size to different brewing methods, enhancing the coffee's taste profile.

The construction material also plays a duty in longevity and upkeep. Stainless-steel parts usually offer longevity and are easier to cleanse, which is crucial for preserving hygiene criteria. Examine the grinder's noise degree, specifically in an active coffee shop or manufacturing setting, where too much noise can be disruptive. Buying a mill that stabilizes these functions can substantially enhance both operational performance and the high quality of the coffee offered.

Optimizing Grinding Process

To attain the best results in coffee prep work, enhancing the grinding procedure is necessary. The grind size substantially affects extraction, flavor, and general top quality of the brewed coffee. Different developing methods need specific work sizes; for circumstances, coffee demands a fine work, while French press necessitates a crude texture. Recognizing the connection in between grind dimension and developing approach is the first action in optimization.

In addition, checking the grinding rate can maximize the procedure. Slower grinding often produces much less warmth, maintaining fragile tastes and fragrances. Alternatively, much faster visit this web-site grinding might produce extreme heat, adversely affecting the coffee's high quality.

Maintenance and Care Tips

Correct upkeep and treatment of industrial coffee grinders are important for making certain optimum efficiency and longevity. Normal cleansing is the foundation of maintenance; deposit build-up can impact flavor and grinding efficiency. It is advisable to cleanse the mill after each use, cleaning down the exterior and removing any kind of coffee premises from the burrs.

Furthermore, inspect the grinding burrs for damage. Plain burrs can jeopardize grind uniformity, so they must be changed as needed. Industrial Coffee Grinder. Regularly calibrating the mill is likewise vital, as this preserves the desired grind size for different developing techniques

Lubrication of relocating components should be performed according to the manufacturer's specifications, as this reduces rubbing and lengthens the life of the tools. It is important to utilize food-grade lubricants to make sure safety and conformity with health guidelines.

Lastly, keep the mill in a dry and steady environment to protect against rust and rust. By sticking to these maintenance and care pointers, operators can improve the efficiency of their industrial coffee mills while guaranteeing high-quality outcome and expanded operational life.

Roi Evaluation

Reviewing the roi (ROI) for industrial coffee grinders is important for services looking for to maximize their coffee manufacturing capacities. A comprehensive ROI analysis assists figure out the monetary stability of purchasing high-grade mills, permitting businesses to weigh the initial costs against potential gains.

Examine the purchase rate of the grinder, including installment and any type of required alterations to existing facilities. High-performance grinders commonly lead to decreased grinding time and increased throughput, which can dramatically enhance performance.

Furthermore, consider the influence on product top quality. Industrial Coffee Grinder. Superior grinders yield an even more consistent work dimension, which can improve taste profiles and consumer contentment, eventually driving sales. By boosting the quality of the end product, businesses can validate greater pricing, causing enhanced earnings

Conclusion

In summary, a commercial coffee grinder plays an essential duty in enhancing both effectiveness and item quality within coffee production. By picking top notch burr grinders geared up with crucial features such as adjustable work setups and durable building, companies can make certain optimal flavor extraction. Regular maintenance is important for maintaining mill efficiency and making best use of customer complete satisfaction. Eventually, the tactical investment in a trustworthy mill adds significantly to improved revenue and competitiveness you can try here in the coffee industry.

In the affordable landscape of coffee manufacturing, choosing the best industrial coffee mill plays an essential function in enhancing both efficiency and item high quality. The two key kinds of grinders are blade mills and burr mills. Within the burr grinder category, there are level burr mills and conical burr grinders, each with its benefits. Burr grinders are generally favored over blade mills, as they supply a consistent grind dimension, which is vital for ideal extraction and taste.

In recap, an industrial coffee mill plays an see this website essential function in enhancing both efficiency and item high quality within coffee production.